Maskless exposure system does not need a photomask because it can generate a printing pattern with a digial micromirror device (DMD) made by the U.S. company, Texas Instruments.。

Not producing photomasks saves cost and time before the exposure process. Also applicable to high-mix low-volume production or experimantation & research use.

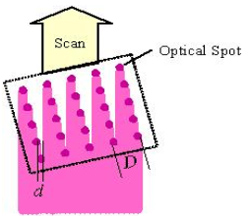

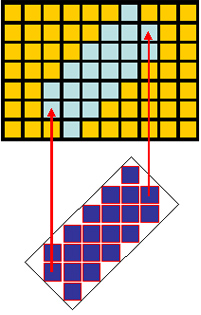

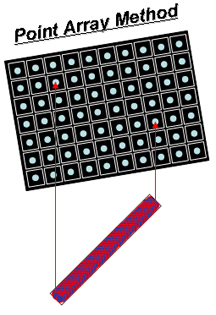

The “Point Array” method

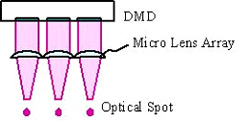

A microlens array is employed so that each microlens condenses a square beam from the DMD’s corresponding pixel into a smaller round spot.

The beam spots are arranged in rows making a certain angle with their scanning direction above the imaging plane. The spots that scan in slightly different positions achieve the imaging resolution higher than the DMD’s pixel size wihtout sacrificing the size of the exposing field.

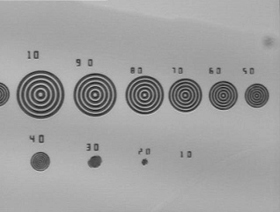

For example, when the optical magnification ratio is 5:1, an imaging resolution of 0.05um is possible.

High speed imaging with 700,000 light beams

- Having our original Data Generation Board (DGB) capable of turning ON/OFF each of about 700,000 light beams realizes high speed imaging.

- For example, a 600mm-long substrate can be scanned in 7 seconds (at an imaging resolution of 1um)

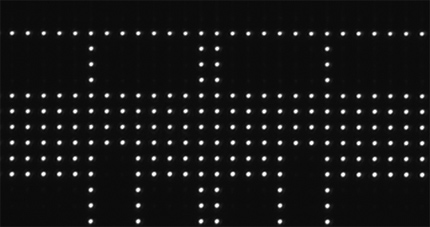

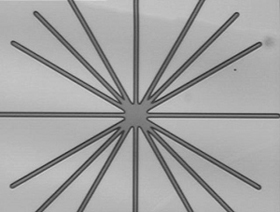

Also good at oblique lines and curves

The “Point Array” method prints an image as a collection of fine dots, it means oblique lines and curves are smooth as well.

It provides the shapes that are well competitive with those of the mask-using exposure.

Invisible stitch between scan images

In the “Point Array” method, the stitching area between two scan images are plotted 50-50 in the respective left and right scan images. In combination with an imaging-position adjusting capability, it makes the stitch less distinctive.

“i2B”, a realtime data transform that enables “soft alignment”and even magnification error correction

- Our original high-speed realtime data transform software enables “soft alignment”: overlaying an image by adjusting the imaging position, without any mechanical stage travel.

- Moreover, magnification correction is applicable to any quadrilaterals (not only a box-like shape, but any shape with four sides and four vertices).

Inteligent Mask “i-mask” reproduces not only the image, but the exposure itself

- Our original data format “i-mask” keeps not only the printing data but the all information to control the exposure system. Only having this format of data enables reproducing an identical exposure.

- A tool to convert your CAD data into “i-mask” format is available.

※Assumed standard CAD format is Garber.