A mask moves during (UV) radiation and controls the energy incident on the photoresist surface, thereby enabling fabrication of 3D microstructures with arbitrary curve or slope.

Main feature

- Our original mirror & lens optical system realizes uniform radiation covering the full exposure area.

- Equipped with gap sensors for non-contact gap making with a good in-plane uniformity, and an alignment system composed of microscopes and a XYθstage for aligning the existing layer(s) on a substrate to a mask pattern.

- In the “Moving UV mask” method (in which a piezo stage micropositions a mask during exposure), the thick resist’s sidewall slope angle is controllable, thereby fabricating 3D microstructures is possible.

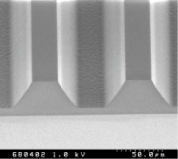

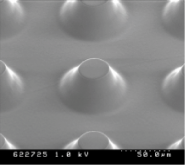

Example of 50μ-thick resist pattern

L/S=50μm

Mask travel =20μm

Dot=Φ50μm

Mask travel =Φ25μm

Main spec

| MUMseries | ||

|---|---|---|

| Mask size | Max 9″ x 9″ x t3.0 mm | |

| Substrate size | Max Φ8″(Wafer) | |

| Light source | Super high-pressure mercury lamp:500W or 1kW | |

| Outer dimensions and weights | Main body dimensions | W2120 x D1305 x H1850 mm |

| Main body weight | 640kg | |

※Custom substrate size, mercury lamp wattage or other special spec available.